Hubei Academy of Aerospace Technology:60kN lever-type force standard machine transformation

1. Project name, model and specification

60kN lever force standard machine control system modification, original model, specification: EEG-6/60kN

2. Transformation plan and function realization

2.1 60kN lever force measuring machine control system reform

2.1.1 Mechanical structure part

(1) Using the existing lever-type standard force measuring machine working mode, retain its mechanical parts and weights。

(2) The original large and small weight loading and unloading mechanism, lever, worm gear reducer, AC asynchronous motor, etc., remain unchanged。

(3) Calibrate lever ratio with high precision dynamometer。

The precise adjustment of the lever ratio can improve the accuracy only by using a high-precision dynamometer to perform graded measurement。

(4) Adjust the level of the whole machine

The level of the main machine, the size of the weight tray level adjustment, eliminate the influence of side force, improve the overall accuracy。

2.1.2 Control System

(1) Redesign the production control system。The system is mainly composed of programmable controller (PLC), touch screen man-machine interface, peripheral control circuit and software, which can be divided into manual control and computer control。To realize the selection, display, setting and control of the test force (weight)。

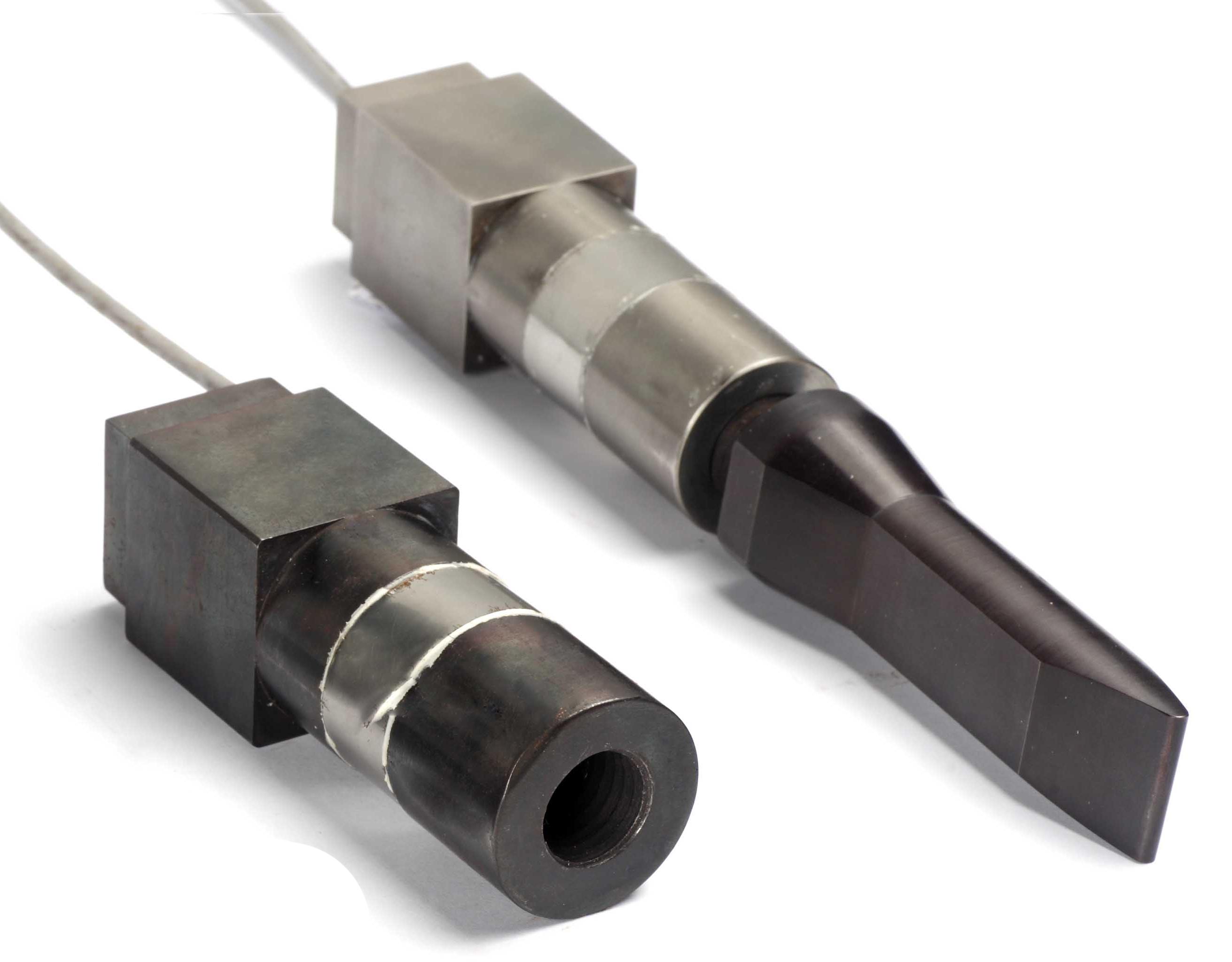

(2) Automatic detection of weight position。The non-contact sensor is adjusted and configured on each set of weight brackets to detect the position of the weight dynamically in real time, and the size (weight) of the pre-applied force value (weight) is displayed on the operation interface. The loading or unloading automatically stops when the set force value is reached。

(3) Replace the lever balance indicating device

2.2 Function Implementation

2.2.After the transformation is completed, the whole control system can achieve the original control function, and has the characteristics of convenient operation, simple and intuitive。The technical specifications meet the corresponding requirements of JJG 734-2001 "Mechanical Inspection Specification of force Standard"。

2.2.2 The measurement software has the function of automatically generating certificate reports and original data records, and users can customize the format of certificate reports and original records。

3. Configure the system

The system configuration is shown in Table 2

Table 2 Modification and configuration of 60kN lever force measuring machine control system

序号 | Component name | 数量 | 备注 |

1 | Programmable Controller (PLC) | 1套 | The Japanese company KOYO |

2 | Touch screen | 1套 |

|

3 | Automatic weight position detection system | 2套 | The Japanese company KOYO |

4 | Control software | 1套 |

|

5 | Test software | 1套 |

|

6 | computer | 1台 | 惠普 |

7 | printer | 1台 | 惠普 |

8 | Precision Digital Measuring Instrument (6000-01-A1) | 1台 |

|

9 | Precision Digital Measuring Instrument (6000-02-A1) | 1台 |

|

3.2 The random data are shown in Table 3

Table 3 Random data

序号 | 名称 | 数量 |

1 | Complete system instruction manual | 1份 |

2 | Electrical design schematic | 1份 |

3 | Electrical assembly drawing | 1份 |

4. Main technical indicators:

0.03%;±4.1 Indicating value error: not greater than

4.2 Repeatability: not greater than 0.03%。

5. Operating environment requirements:

5.1 Power supply: 380VAC, 50Hz;

5.2 Temperature range: (20±2) ℃;

5.3 Relative humidity: ≤85%。