Function summary:

SHT5206 microcomputer controlled electro-hydraulic servo universal testing machine adopts single-space cylinder with upper structure and bidirectional differential cylinder to realize bidirectional pull and pressure control in one space。The rigid structure without gap is adopted, and the test space is adjusted directly by the lifting of the piston, which is convenient and efficient to operate。

The testing machine is mainly used for tensile, compression, bending, shearing and other tests of metal materials.The closed-loop servo control system can automatically and accurately control the test process, and automatically measure the test parameters such as force, displacement and deformation。It can realize the test of equal rate loading, equal rate deformation and equal rate displacement, and can realize the control of force, deformation and displacement in one test, and the control can be smoothly switched between。The software can automatically calculate ReH (upper yield strength), ReL (lower yield strength), Rp0.2 (specified non-proportional elongation strength), Rt0.5 (specify the total extension strength), Rm (tensile strength), E (elastic modulus) and other parameters。

The computer and the measurement and control system collect the test data and send the control instructions, which can automatically control the test process and automatically calculate the test results, and display the test curve and the test result in real time by the microcomputer screen, and print the test report and the test curve by the printer。The system has a return function, after the test, the loading cylinder piston can automatically return to the initial position, can also be returned manually。

Test software built-in standard network interface, test data can be transmitted to the network through this standard interface, the software manual and help documents have detailed description of this interface and the use of configuration methods, network software through this interface and test software data exchange and transmission。

Relevant standards:

GB/T 2611 "General Technical Requirements for Testing Machine"

GB/T 16826 "Electro-hydraulic Servo universal Testing Machine"

JJG 1063 "Electro-hydraulic Servo Universal Testing Machine"

GB/T 228.1 "Metal materials tensile test - Part 1: Test method at room temperature"

Technical index

Specification and model | SHT5206 |

Maximum load (kN) | 2000 |

Accuracy class | 1(0.5)级 |

Relative error of test force indication value | ±1(±0.5)%以内 |

Test force measurement range | 1%~100%FS |

Test force resolution | 1/500000FS (full range ungraded) |

Relative error of deformation indication | ±1(±0.5)%以内 |

Displacement resolution (mm) | 0.007 |

Relative error of displacement indication | ±1(±0.5)%以内 |

Maximum piston moving speed (mm/min) | 160 |

Piston descending maximum speed (mm/min) | 275 |

Test force loading rate range | 0.02%-2%FS/s |

Number of columns | 4 |

Effective distance between columns (mm) | 950×600 |

Maximum distance between drawing jaws (mm) | 815 |

Column clear distance (mm) | 800×450 |

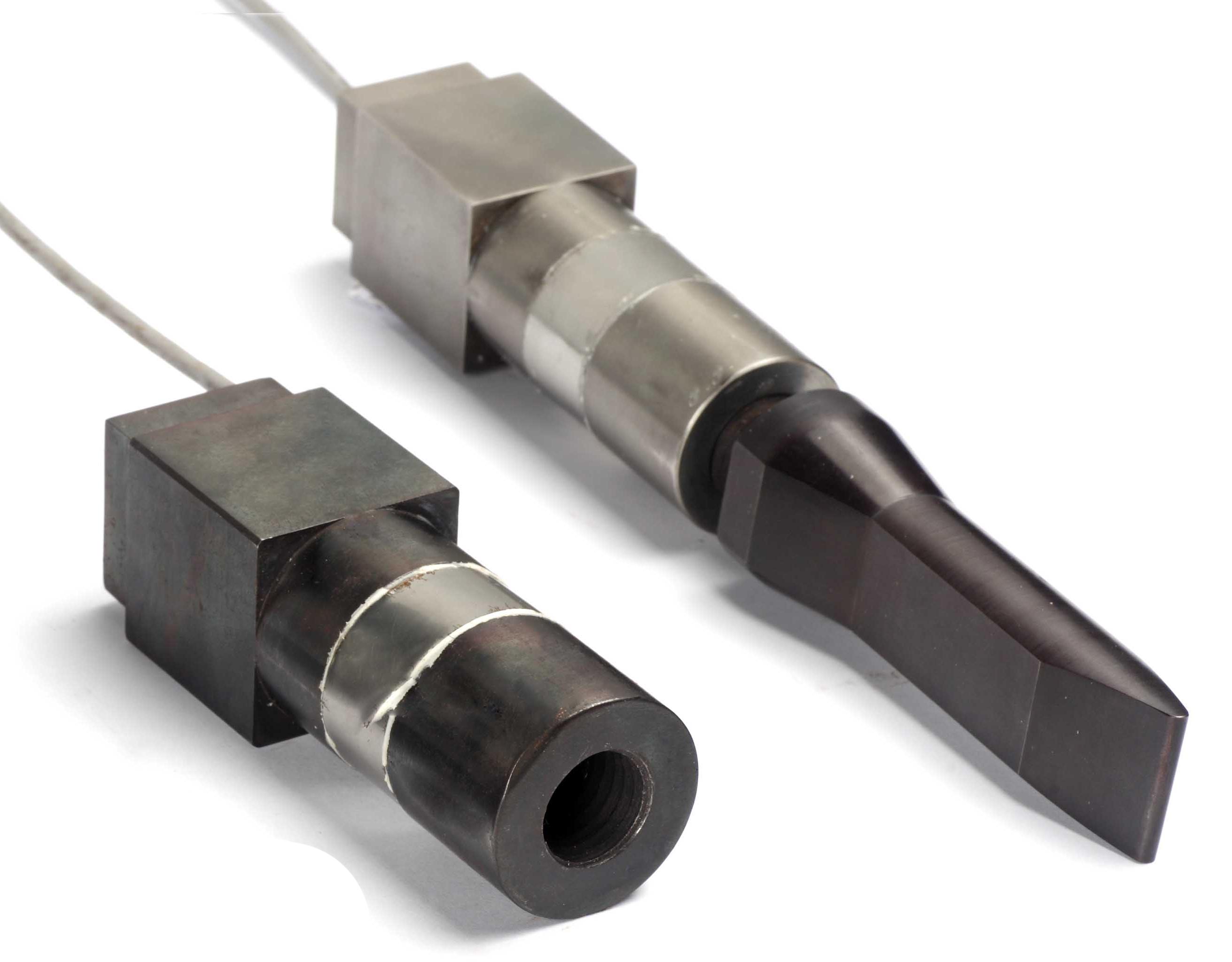

Holding range of round specimen holder (mm) | Φ15~Φ70 |

Clamping thickness of plate specimen holder (mm) | 10~70 |

Pressure plate size (mm) | Φ200 |

Piston stroke (mm) | 800 |

Main machine Dimensions (mm) | 1220 (L) ×980 (W) ×3980 (H) |

Oil source Dimensions (mm) | 1220×600×1150 |

Total power (kW) | 8kW (three-phase 380V) +1.5kW (Single-phase 220V) |

电源 | 3 to 3W+N+PE, 50Hz |

Weight (kg) | 7900 (main engine)+400 (Fuel source) |